You might be wondering, why haven't I heard of a carton stapler before? The simple answer, unless you manage a packing, shipping, or carton assembly operation - you probably haven't come in contact with one of these tools. Want to know what a carton closing stapler is good for? Well, it's all in the name. Learn more about the different types of carton closers and box staplers, applications they excel at, and tips to consider before purchasing - available on the Nail Gun Network.

Before selecting a carton stapler, you need to consider what it will be used for. Aside from the obvious - for use with cardboard - you will want to review the average volume of your operation, intervals of use, the thickness of cardboard or corrugated you are working with, and more. For business owners packing and shipping cardboard boxes in volume, most rely on their carton closing staplers to keep their operation running. Carton staplers offer increased revenue potential, efficiency, and provide a stronger seal versus other fastening agents.

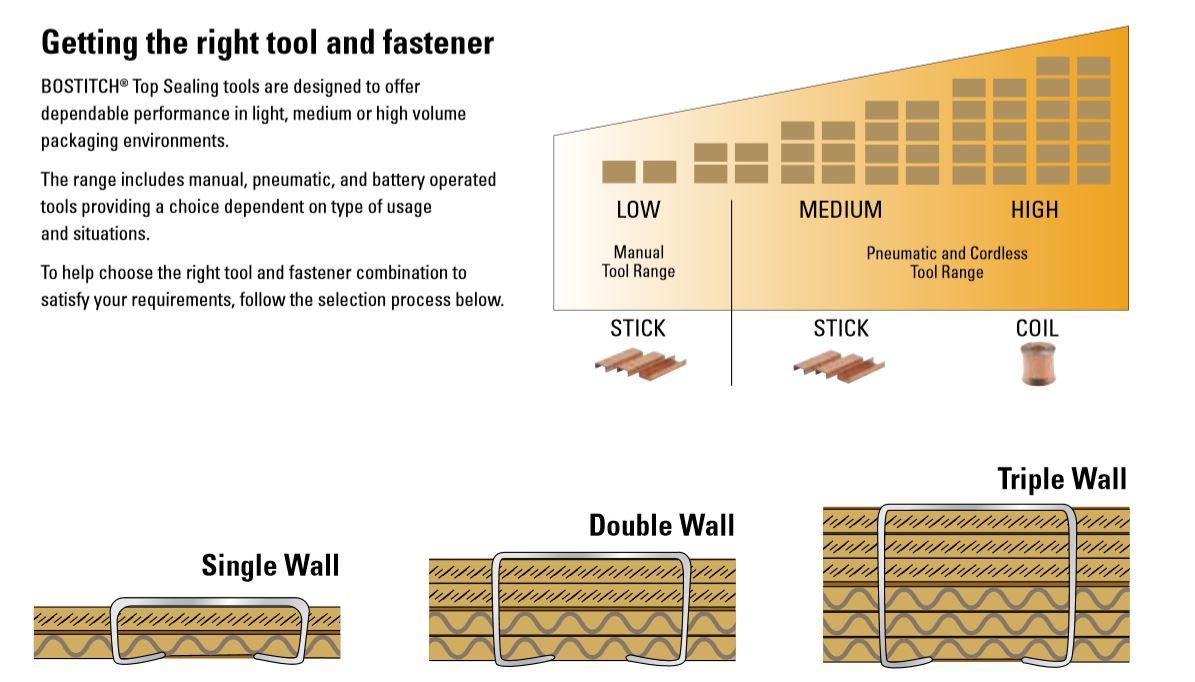

To start, take a look at the thickness of your cardboard. Cardboard boxes are typically available in single, double or triple walls. Most carton staplers can handle single walled cardboard with ease. If you are working with double or triple wall cardboard, you will need a box stapler specifically designed for thicker applications, such as the Bostitch BTFP12182 triple wall carton closing stapler or one of the ISM 3G Series box closing tools.

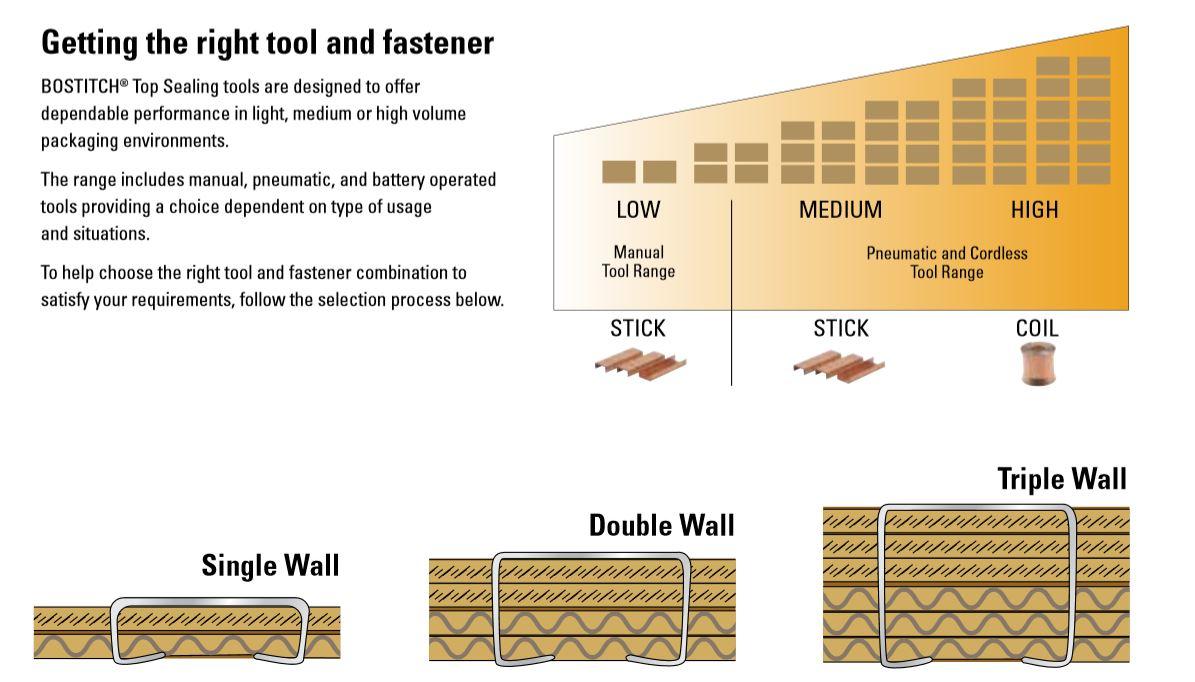

Next, look at your operation's volume. For low volume packaging, a manual carton closing stapler might be sufficient to get the job done. For medium to high volume production, you will need either a pneumatic, electric or cordless carton stapler. In high volume applications, the option for roll staples versus the standard stick of staples is also available.

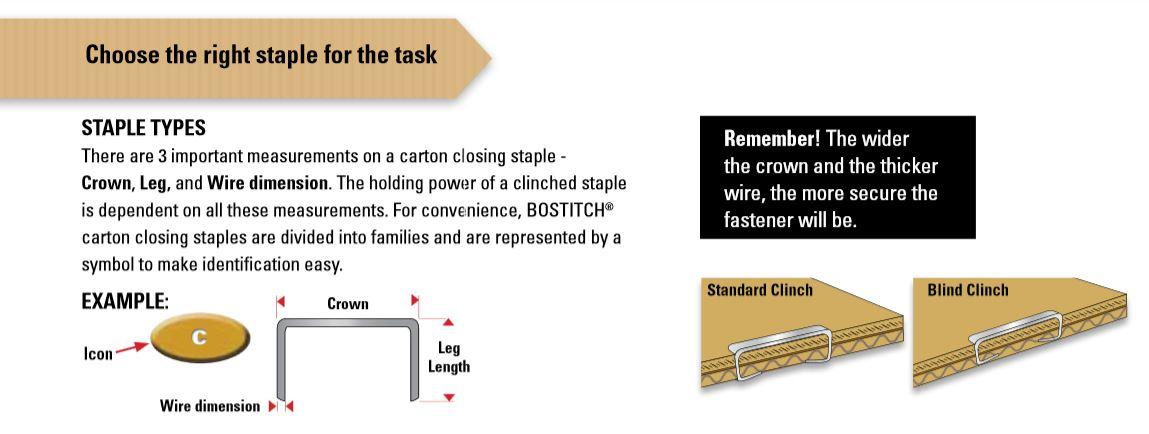

Choosing the right staple for the task is key. The wider the crown and thicker the wire - the more secure the staple will be. Pay careful attention to the type of staple required for your application - this will ultimately determine the range of carton tools you can choose from. Look at the wire dimension (thickness), the crown (width), and the leg length.

Now that we know the basics in choosing a carton stapler, let's look at the different types of packaging staplers that are available.

Top Carton Staplers

Generally speaking, top carton staplers are the most common box closing staplers - especially in low to medium volume packing and shipping facilities. Top carton staplers are excellent for high and low volume carton closing and packaging. Depending on the set up of your workspace, several businesses utilize cordless carton closers, such as the 12-Volt battery powered models by Bostitch, to decrease production time and improve versatility (remember, no hoses or cords).

Plier Staplers

These self clinching staplers are designed for industrial applications in packaging, bedding, displays, set up boxes and more. Recommended for light assembly, packaging, corrugated construction and shoe-making. Plier staplers are primarily intended for manufacturing. Choose between models from Klinch-Pak, Senco, BeA, Bostitch and more.

Post Bottomer Carton Staplers

Post bottom carton staplers are strictly industrial in their function. These box staplers are designed to tackle a variety of cardboard and corrugated stapling applications on assembly lines, or in designated work stations. Post bottomers are too heavy and bulky to be moved around frequently, so they are generally only used in businesses where production is in a fixed location. Choose between manually operated models, which include several options from Josef Kihlberg, or pneumatic models such as the Bostitch F84-138 manual box bottomer carton stapler.

Bench Mounted Carton Staplers

Bench mounted carton staplers are designed for light assembly, typically in manufacturing. They are excellent for clinching end flaps together, five-panel folds, overlap box closure, bag closure, tagging, shoes, and other cardboard applications requiring light assembly. Nail Gun Depot features a variety of BeA bench mounted carton staplers.

~ The Nail Gun Depot Team

this is the description of the boxes we get from our manufacturer Romanow Packaging

F O L G L U E I N P L A I N item # 4 5 0 9 3 1

3 3 1 / 8 X 7 1 / 2 X 3 5 1 / 8

E C 4 8 D W

means if cartons height is 8". we should staple 2 or 3 or .... pins.

Plz guide me.

Thank you for explaining the different issues regarding choice of stapler for packaging, but I still have one question I have been unable to find any answer to - can a top stabler be used for sealing the bottom of a cardboard box? Everywhere I see images and videos of top staplers closing the top and post bottom carton staplers taking care of the bottom - what is the difference?

I have a need for a stapler for 2 layer cardboard and the bottom should hold about 80 pounds - what would be the ideal solution for this?

Thx.

It is not recommended to use a top carton stapler for box bottoms. A post bottom carton stapler is designed specifically for the cardboard box bottom, which helps ensure the corrugated packaging will be held together firmly.

We do sell top carton closing staplers that can handle double - and even triple wall cardboard - but I'd still recommend getting a bottomer stapler for the box bottom.

I'll provide links to our <a href="http://www.nailgundepot.com/top-carton-staplers-4457-products.html" rel="nofollow"><strong>top carton</strong></a> and <a href="http://www.nailgundepot.com/post-bottomer-carton-staplers-products.html" rel="nofollow"><strong>post bottomer stapler</strong></a> product categories, but without knowing your power requirements, it's hard to recommend a specific tool.

If you would like a specific product recommendation, please respond to this comment, or email <a href="mailto:sales@nailgundepot.com" rel="nofollow"><strong>sales@nailgundepot.com</strong></a> with your product requirements.

Thanks for your question.

Thanks

I'm also going to provide your email to her, so she can contact you directly to help source the right tool and staple for your operation.

Thanks for contacting Nail Gun Depot!