If you live in a region susceptible to winter weather, as most North Americans do, it's crucial that your pneumatic tools and air compressors are properly maintained for the cold. If at all possible, it's best to avoid using pneumatic tools in temperatures below freezing - however, for contractors that depend on their tools for a living, there are measures that can be taken to help protect the integrity and performance of your tools or compressor from the freezing cold. Find out more - right here on the Nail Gun Network.

Let's start with cold weather maintenance tips for an air compressor. As an air compressor runs, moisture builds up in the tank from compression taking place. While it is good practice to make sure the tank is drained after every use (particularly in damp, humid climates), it is especially important in cold or freezing temperatures, as this water moisture can freeze and seize up the entire unit. To drain your compressor, simply release the drain valve, which is typically located on or near the bottom of the tank. Make sure you do this while the tank is under some pressure - then, take care to close the valve or valves until the air stops leaking. NOTE: never twist the valves with pliers.

Other cold weather tips for your compressor, consider using heat lamps to keep the compressor regulator from freezing. You can also put your compressor on a continuous run cycle, if available on the model you own. Need help picking out a compressor? You can visit Nail Gun's Introduction To Air Compressors.

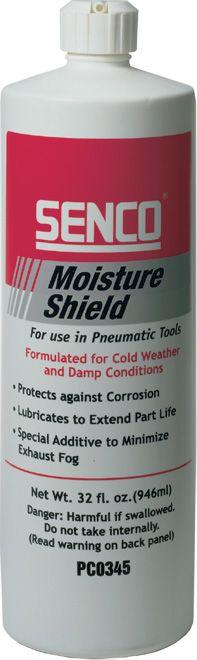

Now that your compressor is running, let's take a look at cold weather maintenance for pneumatic tools. First and foremost, make sure you are lubricating your tool with cold weather tool oil, such as Senco's PC1295 Moisture Shield cold weather air tool oil. Using a cold weather lubricant such as this one, is great preventative maintenance that is easy and inexpensive. You can apply a manufacturer approved cold weather tool oil to the tool itself - and the air line.

Other cold weather tips for your pneumatic tool, when starting use in freezing temperatures, as the compressor builds up, WITHOUT fasteners in the tool, hook up your pneumatic nailer or stapler to the compressor and fire @ 40 PSI to help warm up the tool before use. NOTE: Make sure the tool has no fasteners in its magazine before/during firing to avoid damaging the tool or work surface and prevent injury.

You can also rotate pneumatic tools - while keeping the idle tools warm. Using pipe insulation that fits over a coupler is another method that helps create a barrier between the tool and cold air. Can't decide which pneumatic tool is right for your application, check out Nail Gun's Construction Tool Index.

We can't guarantee all of these tips will work for everyone, but if used appropriately, they might save you some major repair expense and downtime on the job. Tools and compressors that are not maintained or used as the manufacturer specifies are susceptible to damage and destruction - so save yourself time, money, and a major headache, and prepare your equipment for responsible use.

~ The Nail Gun Depot Team