Growing in popularity and demand, stainless steel nails, staples and screws are quickly becoming the fastener of choice for premium-quality construction projects. While these fasteners are costlier than those made of other materials - they provide the best protection against rust and other deterioration causing agents. Find out how to select the right grade of stainless steel for your project - here on the Nail Gun Network.

Before we start, let's take a brief look at stainless steel itself. Stainless steel is composed of high amounts of chromium, the element that provides corrosion resistance and additional strength to stainless. It is chromium that gives the steel its rough, adherent, corrosion resistant surface. Its self-healing properties (if oxygen is present) provide further enhancement. A popular metal for its appearance, stainless steel is now becoming an integral component in quality-construction projects - particularly in coastal regions.

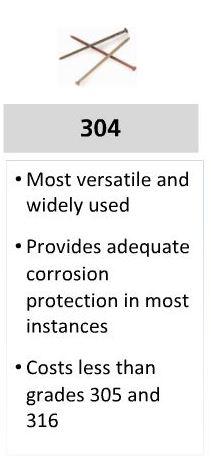

There are several different grades of stainless steel fastener, however, most contractors will be most familiar with three main classes: 302, 304 and 316. The lower grade option, 302 stainless steel has a greater carbon count, reducing its corrosion resistance. A less expensive form of stainless steel, 302 is softer and more likely to strip. This type of stainless is best used in projects where corrosive agents are less prominent - such as interior projects.

The next major classification, 304 stainless steel is the most widely recognized stainless product available. Known for its balance of nickel and chromium, 304 grade stainless steel is more durable and offers better corrosion resistance than 302 grade. Less expensive than its 316 grade cousin, 304 stainless steel fasteners typically offer the best balance of corrosion resistance, versatility and cost. This grade of stainless steel typically provides an adequate amount of strength and protection in most instances.

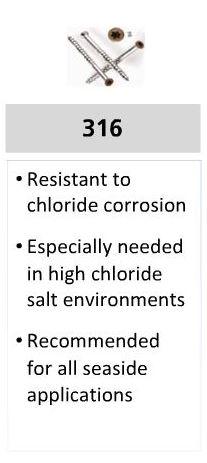

An even stronger form of stainless steel, 316 grade stainless is the preferred grade for projects where exposure to high chloride salt is prevalent. Popular in coastal regions, 316 stainless is resistant to chloride corrosion - and is recommended for all seaside applications. The downside to 316 grade stainless, it is costlier than its lower-grade counterparts.

In addition to these three grades, look for 18-8 as a generic grade for stainless steel. The grade of 18-8 can refer to grades ranging from 302-305. Generally, you will not want to go below the rating of 18-8 in terms of stainless steel fasteners.

Make sure to select the appropriate grade of stainless steel for your project. Depending on the environment of your application, choosing the right grade of stainless steel can determine the long-term quality of your project. To find the appropriate stainless steel fasteners for your tool on Nail Gun Depot, simply search the applicable category of fasteners and choose from items labeled as stainless. Be sure to check back often, as we continue to expand our stainless steel nail, staple and screw product lines.

~ The Nail Gun Depot Team

Thank you for your interest in Nail Gun Depot!